Improve profits and maximise efficiency of your warehouse

Products

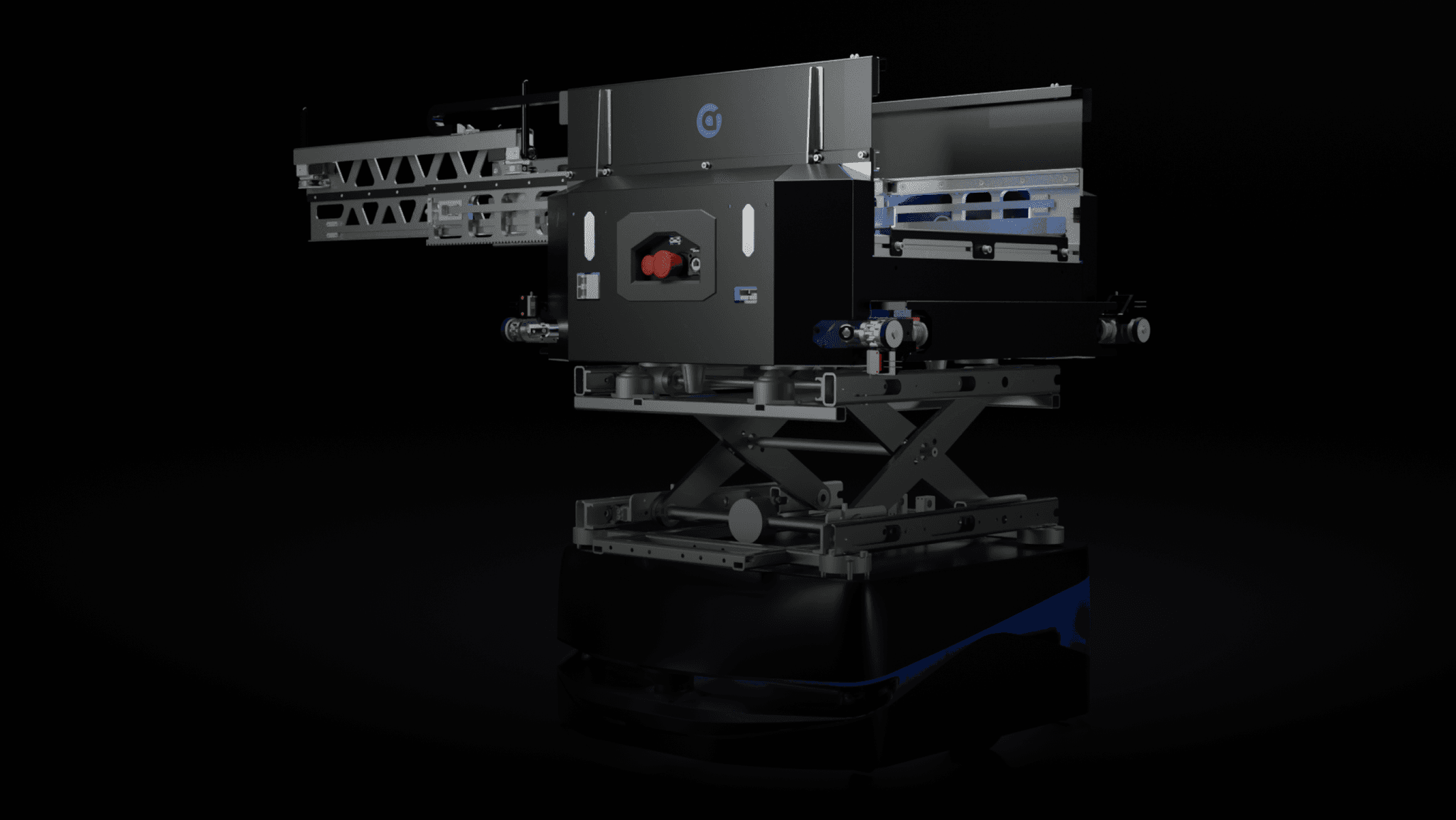

AccioPick Air

A truly one-of-a-kind bin-to-person solution creating performance, efficiency and space saving milestones within the order picking use-case in fulfilment centers.

AccioPick Pilot

Where robotic precision meets human ingenuity. An uniquely assisted order picking offering to unlock the most productivity out of the warehouse workforce.

AccioOS

The brains behind the operation. A state-of-the art solution to analyse, assign and integrate processes from anything and everything between receiving and dispatch.

Speeding through the fastest growing industries

E-Commerce

Accio's e-commerce solution redefines efficiency, picking a variety of products swiftly to keep up with online shopping demands.

Groceries

Revolutionising grocery supply chain: Accio's automation ensures every fruit and cereal box is picked with precision and speed.

Pharma

In the world of pharmaceuticals, Accio's picking automation guarantees meticulous handling and accuracy for every medicine.

Industrials

Accio’s automated picking solutions are the best match for the complex supply chains and manufacturing as well as assembly processes in an industrial manufacturing plant.

Automobile & Auto Ancillary

In the automobile sector, Accio's automated picking handles diverse components with unmatched precision, streamlining assembly lines

3PL

As more companies shift their warehouse operations to 3PLs, the need for robust technological solutions in the industry have increased. Accio’s automation solutions prove to be ideal for a dynamic 3PL environment handling a range of SKU types.